RAMMSTEIN - Stadium Tour 2022

Concerts & Touring

Rammstein, known for their spectacular pyro and fire-fueled shows, full-force industrial metal sounds, uncompromising lyrics and dynamite live performances pick up the second leg of their 2018 European stadium tour rescheduled to 2022 due to covid related event-bans. And here we are again. Rammstein played a first live rehearsal concert in Prague May 11th in front of a few hundred fans. WI are so thrilled to be working again with one of the highest profile live bands on the planet. With a full integrated WIMOTION set up perfect control and synchronisation is guaranteed of individual as well as group moving chain hoists utilising SIL3 group position monitoring.

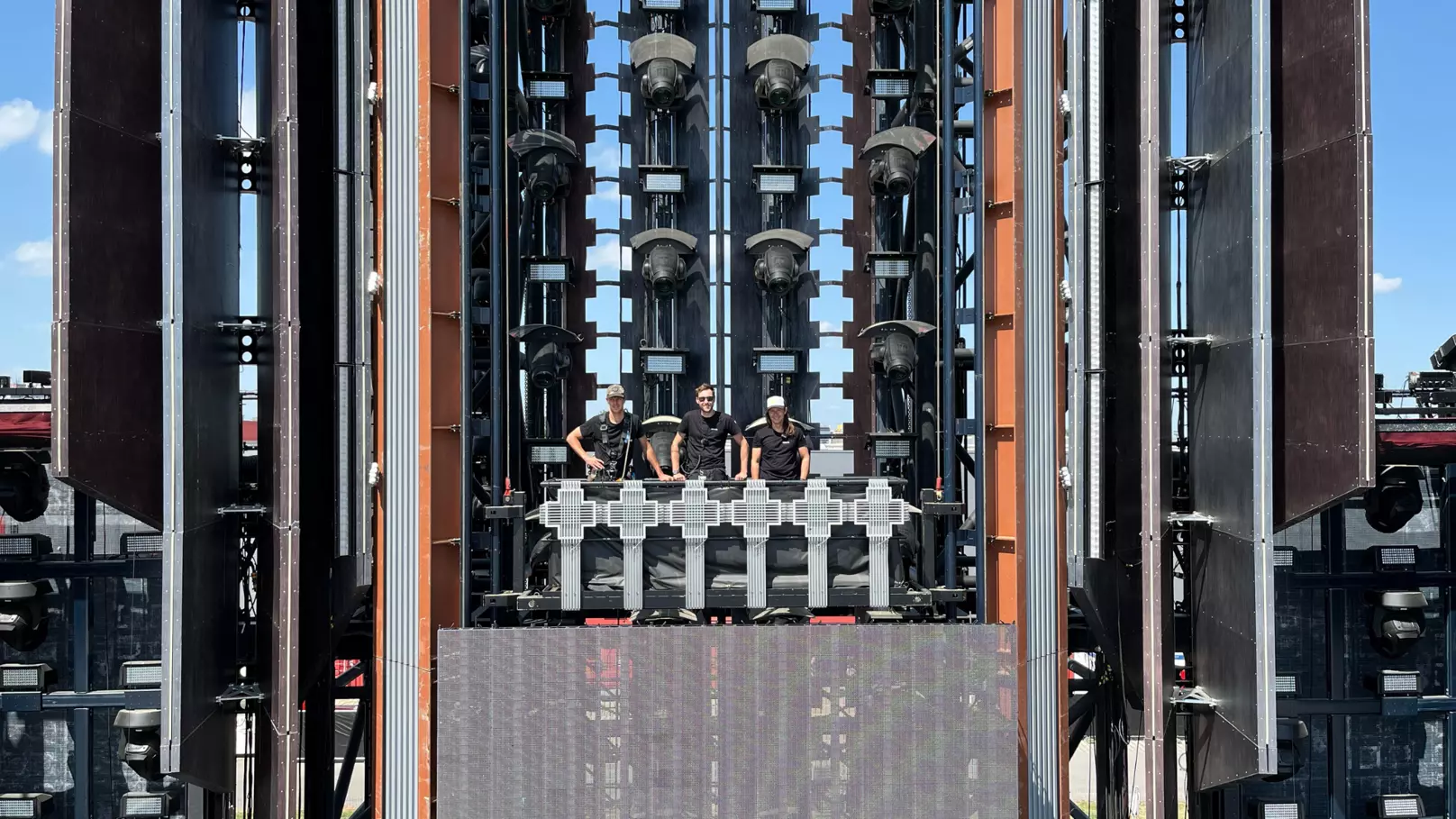

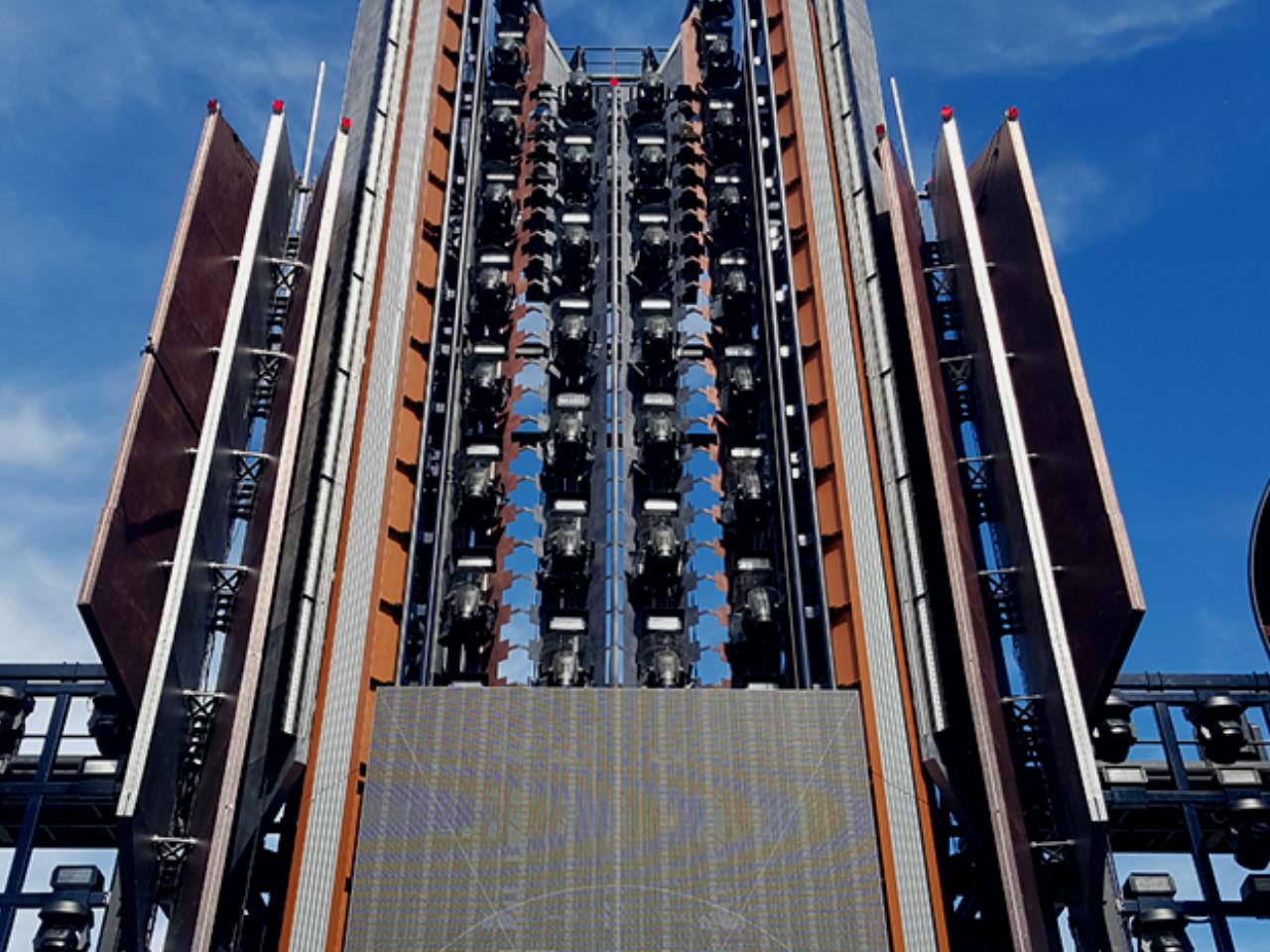

MOVING VIDEO SCREEN AND PLATFORM

The centerpiece of the main tower is formed by a 5m wide by 9m high HD video screen moving 27 m up and down the tower. The screen is wind braced and guided along a set of vertical rails to allow an in-use wind loading of 15m per second. To top off this demanding but hugely exhilarating project, WI created a scenic lift platform that raises the 6 Rammstein band members 26m above the main stage. A total of 10 WIHOISTS are used to move the video screen and band platform. Both can travel at speeds of up to 0,4 meters per second.

The centerpiece of the main tower is formed by a 5m wide by 9m high HD video screen moving 27 m up and down the tower. The screen is wind braced and guided along a set of vertical rails to allow an in-use wind loading of 15m per second. To top off this demanding but hugely exhilarating project, WI created a scenic lift platform that raises the 6 Rammstein band members 26m above the main stage. A total of 10 WIHOISTS are used to move the video screen and band platform. Both can travel at speeds of up to 0,4 meters per second.

WIMOTION INTEGRATED CONTROL

The WIHOISTS are controlled by the WICONTROLLERS, guaranteeing a SIL3 safety level. At the heart of this machinery system is the software that deals with the individual and group synchronisation of all the moving hoists using SIL3 group position monitoring. Using the WIDESK with touch screen enabled user interface and running WIMOTION software, the operator can joystick the hoists into position. WIMOTION allows for the easy setup of group halt options, enabling a position lock for all motors in a group and to set the maximum group and individual channel loads.

The user interface is complemented with a ES-Commander unit and a SIL3 group position monitoring system providing protection against loss of the group synchronisation. The ES-Commander also acts as Emergency Stop and Hold-to-run hub for all devices.

The WI ES-Commander monitors SIL3 upper and lower data per group and limits for all dual-encoder WIHOISTS thus safely halting movement in case of positional discrepancy.

This innovative safety system concept allows hassle-free plug-and-play configuration of daisy-chained drives and a variety of safety signal distribution modules for the most flexible setups.

BACK WALL WISTRUCTURE

WI has designed and built 6 back wall structures which are part of the set and contain integrated lighting elements. These form a grid-like structure of 5 wide by 7 high sections, each measuring 6 m wide x 11 m high with 320 integrated moving heads.

All the lights are rigged on integrated mounts that slide over the grid structure and into place. WI’s design means they remain on the structural beams during transport, making it extremely fast to install these 6 major structural elements.

TRON FASCIAS

WI has also created a set of tron fascias as they are called, 8 in total, 6 which are in between the back walls, with 2 rigged on the main left and right pod towers, and 2 more on the upstage pod towers. All the trons have integrated RGBW led strips and Color Force LED battens in bespoke waterproof housings. The fascia’s vertical splits were dictated by the dimensions of the LED battens, with 42 units of the 72 inch version and 10 of the 48 inch version integrated.

All tron and fascia structures have digitally printed scenic panels to guarantee a consistent look and to add durability.

Manual handling is minimized because all elements can be loaded in and out from their custom built touring dollies by their own overhead-rigged WIHOISTS whilst being guided in vertical tracks.

CENTRAL TOWER

The 400m² central tower which has 23 Fascia panels in 2 stacks of 11 and 1 stack of 10 on the front – is also a WISTRUCTURE, made up from 4 vertical rails, each loaded with 11 moving lights and 10 strobes.

KABUKIS AND PYRO TROUGHS

WI was also asked to create an easy-to-rig system for 10 kabuki drops. 6 of these are deployed in the back wall areas with 4 more on the freestanding field towers. The kabuki frames each have 4 integrated kabuki brakes, can be loaded with the drapes, rigged from ground level and transported in their custom built touring dollies.

As an addition to the STAGECO-built band roof, production commissioned WI to create an easy to rig, yet neatly integrated pyro trough along the downstage roof edge holding a variety of pyro and flame devices complete with related wireless control electronics.

ON THE ROAD AGAIN

All this is coordinated for WI by Koen Peeters and Hans Willems, asked onboard in 2018 by the tour’s technical consultant Jeremy Lloyd of UK based WonderWorks. They have worked closely with Rammstein’s own creative team, a collaboration between lighting designer Patrick Woodroffe from Woodroffe Basset Design (WBD), production designers Wieder Design Studio and WonderWorks.

The band themselves are also very involved in their stage presentations.

A total of 72 tons and 10 trailers full of custom equipment was delivered from WI back then in 2018 in just 14 weeks – a great testament to the overall collaboration of the many departments involved in creating this amazing show, and to the teamwork and talents of our own WI team.

The WI moving video and band platform systems are being managed on the road by 2 dedicated WICREW, while the scenic equipment is being managed by the production crews.

Spot on technical development tour support and 1st class crew: Nicolai Sabottka, production manager

CREDITS

- Technical Coordinator: Jeremy Lloyd - Wonderworks

- Tour Director: Nicolai Sabottka

- Stage manager: Björn Harder

- Show Design: Woodroffe Bassett Design

- Lighting Design: Roland Greil & Patrick Woodroffe

- Production Design: Florian Wieder

- Set Design: Wieder Design Studios - Cuno von Hahn

- Scaff and steel supplier: Stageco Belgium

- Lighting Supplier: Neg Earth Lights

- Video supplier: Solotech

- Blumano: SIL3 documentation commissioned by WICREATIONS

Our Awesome WICREW on the job: Pieterjan Nouwynck, Niels Alens and Neil Coffey

- WI project lead: Koen Peeters

- WI chief engineer: Wessel Fortuin